Self-contained breathing apparatus

As breathing apparatus generally refers to all devices that are used for respiratory protection, ie protection against materials, particles or organisms that may enter through the respiratory tract into the body offer.

Europe will respirators are respirators according to the EN 133 in the classes

- Self -dependent Respiratory protection: Respiratory connection and filter

- Supplied air respirator protection: Respiratory connection and a device for supplying non-contaminated breathing gas divided.

Respirators are used both in industry and in the various relief organizations, such as fire or rescue services.

- 2.1 Use

- 2.2 Free Portable Vacuum flasks 2.2.1 container units (BG) 2.2.1.1 structure

- 2.2.1.2 Pressure Control

- 2.2.1.3 Safety measures

- 2.2.1.4 How to use

- 2.2.2.1 structure

- 2.2.2.2 application

- 2.3.1 Breathing Apparatus

- 3.1 DIN - Standards

- 3.2 European standards

- 3.3 Guidelines

- 3.4 German regulations

Convection -dependent respiratory protection

Before the use of filtering devices must be ensured that at least 17 vol - % oxygen ( with CO filters at least 19 vol - % oxygen ) is present in the air we breathe and which are known to be filtered substances; otherwise is always a supplied air respirator use. The operating limits of filter devices are determined by the performance of the filter. The substances or areas for the individual filters are likely to be specified by color coding and letters on the filters. Further specifies a maximum absorption capacity of the filter. Since inhalation in the mask creates a vacuum, pollutants can enter into the airways about possible leaks. Therefore, after applying the respirator, a leak test is performed.

In medical practice often called for the mouth - nose mask surgical masks are used, which are intended to prevent droplet infection by pathogens originating from the carrier to protect the patient. Surgical masks protect the wearer even though not from infection. Due to the excessive leakage surgical masks are unsuited and therefore do not fall under the description contained breathing apparatus. Studies at the Institute for Occupational Safety and German Social Accident Insurance have shown that the carrier is much better protected through the use of particle-filtering half masks.

Filter devices

A filter device consisting of a respirator (e.g., breathing mask ) and one or more filters. The filter units were formerly referred to as gas mask.

- Filter can be divided into: Removes gas filter, the gases as an absorption filter (usually activated carbon) or catalytic filter ( for carbon monoxide) from the air

- Combination filter which retains both gaseous and solid and / or liquid aerosols from the air

- Particle filter, the solid and / or liquid aerosols removed from the air, such as asbestos, smoke, fog

For filters, make sure that most, especially gas filters only have a limited life. After removing the seals, a filter is only a maximum of six months can be used as long as he has not come into contact with pollutants. However, he loses in this period continuously at capacity, so driving a filter guide is highly recommended, as well as regular monitoring and, where applicable, the exchange and the filter is not used.

Wear self-containing breathing protection

Under self-contained breathing apparatus to be understood, which isolate the respirators support from the ambient atmosphere and supply of breathable gas from a non-contaminated source. These devices are therefore also known as Insulating and consist of a facepiece and an air supply device.

Vacuum flasks and can be divided into:

- Free portable containers Equipment

- Regeneration devices

- Not freely transferable Compressed air line breathing apparatus

- Fresh air hose breathing apparatus

Use

If the ambient air too little oxygen, less than 17 vol - %, or toxic gases are present, which can not be absorbed by gas or combined filters and is the type and / or concentration of the respiratory poisons unknown, supplied air respirator must be used.

Most free portable Vacuum flasks are used for example SCBA. Due to the limited amount of air, however, the operating time is usually 15 - limited 30 minutes. The duration depends on the age of the breathing apparatus wearer from physical capacity and the type of load in use. If a longer period of use of sometimes several hours required (for example, in mining or in the tunnel use ), so-called long-term devices ( for example, with 2 CFRP bottles of 6.8 l volume and 300 bar filling pressure ), breathing apparatus or rebreather used.

As in use at the fire is difficult to determine whether oxygen in the ambient air is really enough available, mainly the self-contained breathing is employed.

Free portable Insulating

Container units (BG)

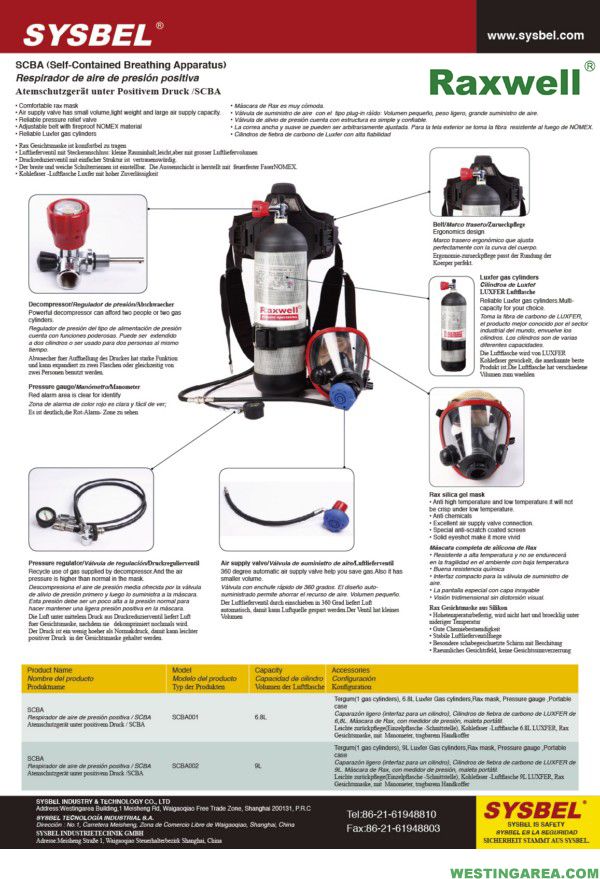

In this type of devices of respirators carrier performs the necessary breathing air in air tanks with them, so they are also referred to as compressed air breathing apparatus (PA ).

It should be noted that it is in the compressed air around especially purified and de-oiled breathing air according to DIN EN 12021 and the containers are therefore referred to as breathing air cylinders.

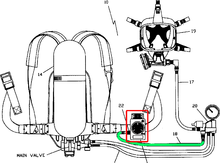

Construction

The usual respirators have bottles in which the air is stored with 200 or 300 bar. The bottles can be made of steel, of glass-fiber reinforced plastic (GRP ) or carbon fiber reinforced plastic (CFRP). Since you can not breathe with this high pressure, the air, is in front of the respirator, breathing regulator, the pressure reducer is built out. This reduces the air pressure of 200 and 300 bar, the so-called medium pressure 5-8 bar (depending on device type). The regulator is a breath -controlled metering device which reduces the pressure at a respirable man-made low pressure ( in millibar range) and only the amount of air releases, which one inhales. There regulator in normal pressure and overpressure design execution. In normal pressure type only the inhaled air volume is released. In the embodiment, the entire pressure respirator is pressurized to prevent the ingress of pollutants into the mask.

At 200 bar devices two bottles, each with 4 liter capacity are common. Arithmetically 1600 liters normal air and an operating time of about half an hour.

300-bar devices usually have a compressed air cylinder of steel with 6 liters ( 1,636 liters breath ) or one or two composite cylinders (CFRP ) each. 6.8 liters ( 1,854 or 3,708 liters breath ).

( The law for rough calculation convenient to use Boyle's law, according to which the product of pressure and volume is constant, is strictly valid only for an ideal gas and only for isothermal changes of state. During filling of the bottles but heats the air, the change of state is not isothermal, but adiabatically. Moreover, air is not an ideal, but a real gas, so you would need to use the more complex van der Waals equation instead of the law of Boyle -Mariotte. )

Long -duration breathing apparatus have two 300 - bar cylinders and are mostly for reasons of weight of a composite material, in particular CFRP.

The cylinders are fastened on a carrying frame that is padded to better carry or cup-shaped. The straps and the waist strap are adjustable and are tight when worn. They are flame retardant and made of rot-proof material.

Pressure control

To check you have a pressure gauge ( also called pressure gauge ) on which one can observe a continuous basis, the air pressure in the bottle is still. To protect the air goes into the bottle to run out, there is a warning device. The most widespread is the audible warning device in the form of a whistle, at a pressure between 50 and 60 bar - starts (55 bar 5, with older devices 60-68 ) to whistle. Other newer device types use an integrated regulator in warning device that does not consume air as a warning signal. In addition, the warning is immediate and it may not be so easy to get confused. The warning signal is not a retract signal, since, depending on the local conditions of the return may take longer than the air remaining ranges. Also important are performed respiratory protection monitoring, regular pressure control as well as the calculation of the retreat path ( twice the march route ). The retreat will go forth in parties competed and depends on the respirators carrier with the greatest breathing air consumption (see Using principles of FwDV 7 respiratory protection).

On older devices, but which no longer conform to the norm, there was a so-called resistance warning. Breathing resistance 50 bar higher and you had a lever directly on the device to tilt back can breathe normally - It was at a pressure drop to 40. Since some carriers include slightly panicked, this species is now usually no longer used.

Security measures

Another new security measure especially in self-contained breathing apparatus is the so-called Totmannwarner or motion alarm. The Totmannwarner is a small electrical device about the size of a cigarette packet. It responds, if there has been no movement in a given time interval. Then first hear a pre-alarm, then followed by a louder acoustic and an optical signal. If a party is in danger and urgently needed help, even an emergency button can be pressed, immediately activates the alarm said. Therefore, the device is officially referred to as " distress beacon ". The alarm can be turned off manually at any time. The Totmannwarner is still no standardized instrument, yet he found in many fire departments use. Its use is advisable, although in the purchase and maintenance quite expensive.

How to use

Before wearing the breathing apparatus there is a complete ban on alcohol, even with colds or hay fever, you should make no bets with rebreathers. The additional breathing resistance, in addition to the actual work, the body heavily loaded. Anyone who is not fully fit, can possibly get faint or even pass out. Before wearing the breathing apparatus support, the device must check (visual inspection and use of accelerated test ). The latter takes place, in which you first open the cylinder valve and observe the pressure gauge to whether the bottle has enough pressure. In this case, the cylinder pressure must not vary more than 10 % of Nennfülldruck, so it must bar 180-220 for 200 bar cylinders or be 270 and 330 bar at 300 bar cylinders. After that the cylinder valve is closed again. Now the pressure drop in one minute shall not exceed 10 bar. The remaining in the medium pressure air is then slowly deflated until the warning signal will sound bar at a pressure 60-50 over the regulator. Thus, the warning device is checked. If the device has two bottles, so this must be done separately for each bottle. Now the cylinder valve is fully opened and the respirator can be created ready for use.

Although the breathing resistance is less than with filter respirator, the institution still physically suitable and healthy as it can easily lead to cardiovascular problems and dizziness otherwise. Furthermore, the protective clothing for fire fighters an accumulation of heat ensures because the body heat is not dissipated through the protective clothing. Therefore, the respirators carrier should take before the respirator use enough liquid.

In Germany, the occupational medical examination by occupational health screening G 26.3 for carriers of self-contained, breathing apparatus, the G 26.2 for carriers of medium, umluftun and umluftabhängigem respiratory protection and the G 26.1 for beams of light, umluftabhängigem respirator aged 18-49 years no later performed the examination each year every 3 years and 50 years of age.

In Austria, a respiratory protection equipment rack at the fire department must be at least one year a member of a fire department at least 18 years old and. The fitness test is also carried out between 18 and 50 years every 3 years old. In an age over 50 years, the tests are carried out annually. Requirement for the wearing of respirators is the completion of the appropriate courses at the (state ) fire service training or the corresponding training outside of schools.

Regeneration devices

Regeneration devices, also known as rebreathers are also respirators for the self-contained breathing apparatus.

Construction

In contrast to the container equipment they do not provide the complete air for inhalation available, but they have a built- oxygen source. These sources can be oxygen cylinders, liquid oxygen or chemically bound oxygen. In a carbon dioxide filter exhaled carbon dioxide is chemically bound and adds the consumed oxygen from the bottle.

The devices are much more maintenance than the usual at the fire compressed air equipment. Repulping upgrading the equipment requires time-consuming tests and therefore occurs only rarely use sites that take place over a long period, with the aid of " roll-off respiratory protection ."

Application

Before wearing the breathing apparatus there is a complete ban on alcohol, even with colds or hay fever, you should make no bets with rebreathers. The additional breathing resistance, in addition to the actual work, the body heavily loaded. Anyone who is not fully fit, can easily get dizzy spells or even faint.

The advantage of rebreathers is the higher technical service life ( up to 4 hours ), as only a "small" share of the necessary breathing air must be kept in compressed form. The use time is limited more by the degradation of the carrier and through the device.

A disadvantage in addition to the already mentioned, is that the inhaled air is heated by the chemical reaction for the binding of the exhaled carbon dioxide over time. Therefore, it was in the past in the promoters of these respirators when dropping often pneumonia. Modern devices are trying to compensate by cooling systems, increase this, however, the weight of the device.

Because of these disadvantages, they are usually only for fire brigades, in which longer periods of use are to be expected, as used for example in tunnel operations and mining.

Non- free portable Insulating

Breathing Apparatus

In line appliances the breathing air is not removed from containers carried, but the regulator via a hose connection (usually medium pressure, 5 bar) supplied from an external source. The advantage of such a system lies in the elimination of restrictions on the service life and reducing the weight to be borne by the user. The disadvantages are the limitation of freedom of movement and the vulnerability of the hose connection. For these reasons, hose appliances normally in case of fire or mine rescue teams do not, or only at empty air cylinders on "Decontamination space " used. But they are, for example, encountered in commercial workplaces with higher concentrations of pollutants and other low risk.

Exemplary applications of the respirators

- Industry and crafts waste treatment

- Chemical and Pharmaceutical Industry

- Woodwork

- Paint shop

- Fires

- Accidents involving dangerous goods

- Reduction of germs in the exhaled air of the practitioner (eg, during surgery )

- Transport or treatment of patients with infectious diseases (eg MRSA, tuberculosis)

Standards, guidelines, regulations

DIN - Standards

- DIN 58600 Respiratory protective devices - plug connection between the regulator for compressed air breathing apparatus in positive pressure respirator for execution and German firefighters

European standards

- EN 132 Respiratory protective devices - Definitions of terms and pictograms

- EN 133 Respiratory protective devices - Introduction

- EN 134 Respiratory protective devices - Designation of individual parts

- EN 135 Respiratory protective devices - List of equivalent terms

- EN 136 Respiratory protective devices - Full face masks - Requirements, testing, marking

- EN 137 Respiratory protective devices - contained open-circuit compressed air ( SCBA ) - Requirements, testing, marking

- EN 138 Respiratory protective devices - Fresh air hose breathing apparatus for use with full face mask, half mask or mouthpiece assembly - Requirements, testing, marking

- EN 140 Respiratory protective devices - Half masks and quarter masks - Requirements, testing, marking

- EN 142 Respiratory protective devices - Mouthpiece assemblies - Requirements, testing, marking

- EN 143 Respiratory protective devices - Particle filters - Requirements, testing, marking

- EN 144 Respiratory protective devices - Gas cylinder valves

- EN 145 Respiratory protective devices - breathing apparatus compressed oxygen or compressed oxygen / nitrogen type - Requirements, testing, marking

- EN 148-1 Respiratory protective devices - Threads for facepieces Part 1 - thread connection

- EN 148-2 Respiratory protective devices - Threads for facepieces Part 2 - Centre thread connection

- EN 148-3 Respiratory protective devices - Threads for facepieces Part 3 - thread M 45 x 3

- EN 12941 Respiratory protective devices - Powered filtering devices incorporating a helmet or a hood - Requirements, testing, marking

- EN 12942 Respiratory protective devices - Powered filtering devices incorporating full face masks, half masks or quarter masks - Requirements, testing, marking

- 14387 Respiratory protective devices - gas filters and combined filters - Requirements, testing, marking

- EN 14593-1 Respiratory protective devices - Compressed air line breathing apparatus with regulators - Part 1: Apparatus with a full face mask - Requirements, testing, marking

- EN 14593-2 Respiratory protective devices - Compressed air line breathing apparatus with regulators - Part 2: Apparatus with a half mask and positive pressure - Requirements, testing, marking

- EN 14594 Respiratory protective devices - Compressed air line breathing apparatus with continuous airflow - Requirements, testing, marking

Guidelines

- EU Council Directive 89/686/EGW of 21 December 1989 on the approximation of the laws of Member States relating to personal protective equipment

German regulations

- BGR / GUV -R 190 - use of respiratory protective devices ( not valid in the mining sector and the fire station)

- Fire service regulation 7 - Respiratory protection (even with adjustments for the technical relief organization in circulation)