Wood stain

Under pickling is understood in the industrial sector, the treatment of solid bodies to alter the surface with a stain. This dressing can, inter alia, to protect the surface against oxidation ( in metal) or mold ( for wood and fabrics ) are used, but also to color the surface and for producing a mordant mordant dyes are used.

- 2.1 Objective

- 2.2 Procedures

- 2.3 Combination pickling

- 2.4 Processing

Metal and plastic processing

For metal and plastic surfaces pickling is done in the main by an etching by means of aggressive chemicals, usually acids or alkalis. The process is used among other things in electroplating to remove deposited metal layers or to get an oxide-free surface. Often the process is by electric current supported ( electrolysis).

Pickling of ferrous materials

An important process step, the etching in the manufacture of cold-rolled steel bands: the purpose is to remove the formed by the hot-rolling process at the surface of solid combustion, the so-called scale. There are two types of pickling lines: continuous pickling and pickling line. In the continuous pickling which is usually wound in coils tape is unwound, straightened, welded the end of the previous as well as the beginning of the new bands after a cut to an " endless " strip and promoted by hydrochloric acid or sulfuric acid baths. In a pickling line, the coils are handled one at a time, pushed through the system and wound up.

The sulfuric acid process needs due to a selective scale attack by a mechanical pre-treatment, which is usually made of a stretch-bending straightening with a draw ratio of up to 2.5%. The sulfuric acid process is usually operated in steel mills that have in connection with the coke via a sulfuric acid production (coal contains sulfur).

After pickling, the steel strips are rinsed in a water cascade and alkalized in the rule, ie they are (for example NaOH) is immersed in an alkaline solution to neutralize the acid so that no acid remains adhered to the surface. Acid residues would be the bands inevitably corrode. Pickling involves the risk of hydrogen embrittlement of the steel.

Before winding the tape fertiggebeizten is possible to oil the surface and the band edges should be tidied up ( " prune ").

Pickling of aluminum

Pickling of aluminum often used for pre-treatment for adhesive joints that are difficult with anodized or bright-rolled aluminum. The pickling process uses a mixture of 27.5 wt - % concentrated sulfuric acid and 7.5 wt - % sodium dichromate ( Na2Cr2O7 · 2H2O ) as well as the remainder ( 65 wt - %) water.

A somewhat simpler and ungiftigerer process for pickling aluminum for adhesive connections, the use of sodium hydroxide solution.

In the electroplating aluminum is often stained with a mixture of nitric acid and hydrofluoric acid. The treatment with hydrofluoric acid, which was largely banned in Germany, the disentanglement of silicon, which is applied during the production of aluminum into the part and can not be electrodeposited coat serves. The pickling times be a few seconds to a few minutes.

Stains of other metals

The pickling of copper, bronze, brass, red brass or gunmetal with chromic acid mixtures is also known as burning or yellow burning, see Burning ( electroplating ).

--- Yellow stains for gold alloys --- 1 part concentrated nitric acid, 1 part of concentrated sulfuric acid, 1 part distilled water. Water. The mixture is heated to 80 ° C. In use, copper and its oxides, as well as parts of silver in the alloy solve. The result is a richer yellow color.

In the electroplating various electroless and power -assisted pickling process are used. The reason is mostly the activation of the base metal for further coating. These activations are different for each base metal / each alloy. Often may require different pickling small differences of the alloy components.

Woodwork

Objective

The pickling of wood surfaces, various targets;:

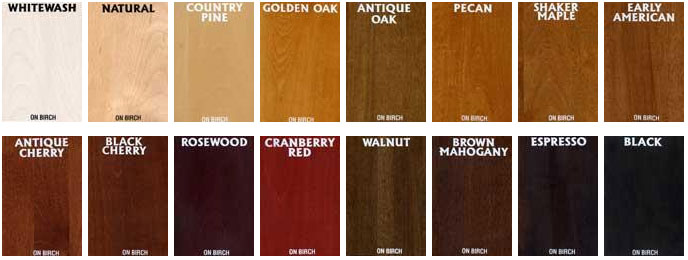

- Emphasis or reinforcement of the natural hue

- Change in hue

- Emphasis on contrasts in the wood grain

- Alignment or leveling of the natural hue

- Alignment or leveling of shades of different types of wood

Method

In the Woodworking two main methods are used: dye stains and chemical etching.

When dye stains powdered or liquid color pigments are applied in an appropriate solution to the surface and pull into the wood. As more color moving into the softer parts of the wood, the grain will be displayed later as a negative. A distinction further in water stains and alcohol-soluble stains (spirit pickling).

In chemical pickling, the tannins in the wood react with the dressing. Since these tannins are more included in harder wood, the grain is preserved as a positive image. With a suitable choice of the mordant, the wood may be not only darkened, but also stained in a variety of colors.

Combination pickling

Räucherbeizen: Makes a very good Porenbeizung and emphasizes very well the medullary rays ( positive stain appearance ), but the coloring is not very lightfast. A well-known example is the smoked.

Bleach stains: By simultaneously applying a stain peroxidbeständigen and hydrogen peroxide natural dyes are faded and the wood fed to an artificial dye, thus a much higher radiation resistance is achieved. Are used mainly for bleaching stains not color stable wood such as wenge, Mansonia and American walnut.

Processing

For dressing, the wood must be pretreated. Adhesive Residues of grinding dust is removed. Using brushes, which are staffed with bronze wire, or a mixed stocking of bronze wire and fiber Remove any excess glue, " cross- grinder " or the like are clearly visible when pickling immediately.

The stripped surface must be protected in any case with the help of a paint or woodstain from damage. Depending on the system used for the treatment of the surface, the color of the surface changed again ( in the jargon, this effect " cheering " is called ).

It is advisable to make prior to the final staining and varnishing of the finished parts Beizmuster from the material to be pickled and to undergo the complete surface treatment process.

Stain penetrates the surface, it is not a superficial layer, which could flake off, deeper minor damage can be re-dyed.