Alternator#Automotive alternators

As a generator ( alternator short ) refers to an electric generator which is also driven by this internal combustion engine vehicles. The alternator supplies the electrical loads on board with energy. In addition, usually a battery as energy storage and buffering to compensate for different voltages on board, so that the power is available even when the engine is running or shut off slowly. The electric starter motor draws its power from it.

The designation as an alternator is historical, as in the early days of the car, the generator only served to supply the vehicle headlamps with power. The previously developed magneto ignition initially remained independent. Also the engine for a long time has been thrown by a hand crank.

- In Anglo-Saxon countries as well as in Switzerland and in the Slavic languages , the name is alternator.

- Some manufacturers call them or generator power generator.

- Sometimes the alternator is also called Dynamo.

- 9.1 Books

- 9.2 brochures

Mechanical drive

The alternator is driven by the engine running as a secondary unit or via a friction wheel of a wheel of the vehicle. The drive is in the car and partially on motorcycles usually with a belt drive, such as ribbed or wedge flat belt. As usual with many motorcycles and gas turbines, the alternator can be coupled directly to the crankshaft also in cars. In this case, its function can also be combined with that of the initiator ( starter generator ).

The generator converts mechanical energy into electrical energy, the required mechanical power is approximately proportional to the electrical power output. Losses due to friction in bearings and depends on the design, the collector or the slip rings. In addition, contact winding losses, hysteresis losses ( magnetisation losses ), losses in the rectifier of AC and alternators as well as losses by the cooling fan on.

Alternators with charge controller

At low speeds, for example when the engine is idling, decreases the electric power generated by the alternator. Is the required power of the vehicle is switched on in the load is higher, the difference is taken from the car battery, in the reverse case, the vehicle battery is being charged. To avoid overloading the starter battery, the voltage delivered by auxiliary equipment in the height will be limited.

The voltage of the alternator would vary greatly with the speed and the connected load at constant magnetic field strength. To control the voltage is changed, the excitation magnetic field strength in the electrically excited alternator. As a control device is used an electronic charge controller. This compares the actual voltage in the electrical system with a built-in voltage reference and controls the magnetization current so that either the maximum magnetizing current or the charge voltage of the starter battery are not exceeded. Advantage of this process is that only the relatively small exciter power of the generator has to be influenced by the controller. Before the advent of electronic controls, these requirements could be overcome by means of an electromechanical regulator with switch contacts.

When excited by permanent magnet alternator output voltage is usually kept constant by thyristors in a combined rectifier / charger. Thyristors as controllable diodes allow similar to a dimmer for controlling the switching- in the conducting direction, so that a more or less large proportion of the power provided by the alternator available rectified and is fed into the vehicle electrical system. In this design, the controller must influence over the excitation power much greater output power of the generator, which became possible with the advent of power semiconductors. Advantage of this design is that it requires no slip rings or collectors and therefore can be operated in oil bath, as in many motorcycles is the case, for example.

Unregulated Alternator

Is unregulated, permanent-magnet alternators found on older motorcycles and bicycles to power the on-board consumers. A degree of voltage stabilization is achieved by the leakage inductance of the winding; at increasing speeds, a higher series resistance in series with the consumer develops due to the increasing frequency. This is a so-called " self-regulation " instead.

On motorcycles, the rotor can with the permanent magnets comprise the inner stator bell- shaped and at the same time contribute more to the flywheel. To supply the ignition system may be a separate coil in the alternator to be arranged either with integrated high-voltage winding or with a separate, external coil.

Species

Dynamo

Until the 1970s alternators were designed as direct current generators. In the stator, the excitation field is formed through the excitation current flowing through it from the magnetic coils, in which the rotor rotates, thereby generating alternating current. This is rectified by the rotor shaft disposed on the collector and discharged through carbon brushes. The disadvantage here is that the carbon brushes need to transfer the full output current of the generator and therefore wear out relatively strong. In addition, through the collector is the maximum permissible speed of the dynamo smaller than that of alternators. Due to the lower transmission ratio of the propulsion by the vehicle engine is the effect that only at a higher engine speed significant electrical power is produced. Under unfavorable operating conditions with a large number of powered-on electrical loads and often low speeds which led to the discharge of the vehicle battery.

Advantage of the direct current generator is that no additional rectification of the generated voltage is required. That was crucial prior to the availability of high-performance semiconductor diodes for their use in vehicle construction. Furthermore, they can be used as a motor to start without a control electronics. In this case it is directly coupled with the motor or turbine shaft.

DC alternators were by the end of the 1960s, predominantly in cars, trucks and coaches. Today you can find them still as occasion generator to aircraft turbines, small gas turbines, and in some hybrid vehicles.

Alternator

Some vehicle manufacturers such as Citroën 2CV in the equipped the vehicles with alternators.

Alternator

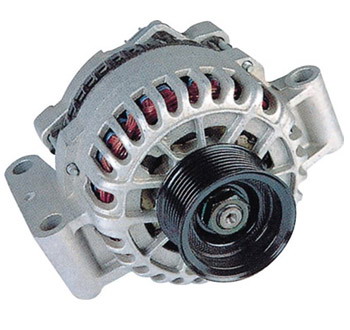

Since the 1970s, three-phase generators have become established as the alternator. Today it come claw pole used. With respect to the direct current embodiment, the functions of rotor and stator are reversed: The excitation field generated by the rotor and induced in the coils of the stator three-phase AC voltage, which is the on-board network is available after the rectification.

Rectifier

The three-phase alternating current is rectified by power semiconductors, which are normally integrated in the generator. Since about the 1990s alternators are protected by internal Hauptstromzenerdioden from dangerous overvoltage and thus suitable for operation without a battery. Older versions without this protection had with the engine running always be connected to the vehicle battery to prevent damage to the rectifier diodes. As the maximum reverse voltage of the rectifier diodes was less than the open circuit voltage of the unloaded generator, the vehicle battery has been required with its low internal electrical resistance as a buffer in order to prevent breakdown of the junction of the diodes and therefore their destruction. The importance of a safe electrical connection between the alternator and the battery. Already corroded connections often led to failures of rectifier diodes.

Dissipation of the power loss

The conversion of the mechanical energy into electrical does not take place without loss, a portion of the energy is converted into heat. In case of insufficient heat dissipation from overheating the unit and is destroyed.

To dissipate the power loss is usually an active air cooling is provided. The associated fan is located on the generator shaft, either outside between pulley and alternator, or in the execution of a compact generator in the housing itself

In some vehicles ( eg Mercedes -Benz W210 ), the generator is equipped with a water cooling system. Although the cooling performance is improved immensely, but also increases the price and need for repairs. This system is used in conjunction with an electric heater, which is to ensure faster achievement of the cooling water temperature. In this case, the generator delivers the full power and heated with its waste heat the cooling water. In addition, an electrically controlled heating element receives power is not required in the system to maximize the heating performance.

Rotor design of a permanent magnet

This design comes in many motorcycles. Instead of the coil windings, permanent magnets are used to energize here. The stator coils are connected in three-phase and only 3 lines lead out of the housing. The controller is installed externally. The advantage over the conventional alternator are attributable slip rings. The generator works as a constant current source. The control is carried out by periodically shorting the stator coils. Since in this case the voltage collapse occurs only low power dissipation. It results from the voltage drop across the effective resistance and the constant current. These generators typically run in an oil bath, which makes additional cooling unnecessary.

Rotor design as an electromagnet

Here, the excitation current has two smooth slip rings is supplied to its height, and thus the induced voltage in the fixed stator is controllable. The excitation current is significantly smaller than the output current of the generator which allows smaller dimensions of the necessary carbon brushes and a longer service life. In addition, compared to the collector of a DC generator a higher speed level is possible, which is why even at idle speed of the drive motor a substantial electrical power is available. Even less space than a dynamo comparable performance is greatly needed.

Indicator lamp in the alternator

The charging lamp has two functions:

- Indication of the correct operation of the generator

- Separate excitation of the generator in the start-up phase

Normally lit ( in vehicle ) with the engine and ignition switched on, the charging lamp and goes out already at a low speed of the unit, at the latest after a single, brief increase in speed from idle, since no voltage difference exists across the lamp. Another behavior indicates defects on the alternator (rectifier, coals, control) or a defect in the lamp, provided the vehicle battery is not discharged. The far more important function of the lamp is the passage or provision of the excitation current. In the state there is no magnetic field in the de-energized generator. Since this is necessary for the generation of electricity, the rotor needs to be powered, so that a field can build up in it. This flows from terminal 15 ( ignition positive ) on the charging lamp by the generator winding to ground (Kl 31) and is characterized by the bulb (4W ) is limited to about 300 mA (without lamp would 2-5 A flow ). During the rotation of the rotor, a voltage is then induced in the stator winding; the available power does to a lesser extent ( the above 2 to 5 A, depending on the speed ), controlled by the charge controller, the supply of the excitation winding of the rotor and can be removed for the greater part as a useful current at the output terminals (B ). If the charging lamp is defective or no battery present / unload them, no external excitation can take place, therefore no voltage is generated even while the alternator. This is also the reason why you can not push car with a fully discharged battery. Older alternators a weak permanent magnet field may have formed during the life of the rotor, which is also without applied voltage. Such machines can also start without charging lamp and electrified in operation. However, this is not an intended effect and it can not be assumed that an alternator without charging lamp or without external excitation can be put into operation. When DC alternators but self-excitation is not unusual since there the induced voltage does not have to overcome the forward voltage of the rectifier diodes before they can contribute to the further excitement.

Charge controller

The diagrams show a "negative regulatory " switching regulator. In addition, there are also so-called " positively controlled " switch controller.

The charge controller has the following responsibilities

- Controlling the voltage produced by the alternator

- Protection against overload due to high output current

- Protection against backflow

Power output

The maximum output power of the generator of luxury cars is about 3 kW. At 14 V voltage can thus flow an electric current of up to 210 A. These high currents all contact points are highly loaded. Even minor corrosion can result from the increased electrical resistance to an unacceptably high heating. In the same manner, this applies to the compounds of the alternator to the engine block and to the bodywork of the vehicle battery.

Terminal designations

The terminals of the alternator in cars have the following names or terminal designation.

- 61 loading control

- Called B Battery positive with " 30"

- B- battery negative with " 31 " refers to ( mass )

- D Dynamo Plus, also corresponds to the terminal " 61"

- D- Dynamo negative ( this term is found only on DC generators or AC generators with external controller )

- DF Dynamo field ( this name is found only on DC generators or AC generators with external controller ). Note: The term DF can also be found on older alternators with paged control on the connection of the field winding to the controller and the controller itself (Wagner electricians customer automotive technology )

- DF1 Dynamo field 1

- DF2 Dynamo field 2

- W tachometer (often in diesel vehicles )