Bessemer process

The Bessemer converter is a cylindrical refractory vessel, with the steel from pig iron is produced. The method is named after its developer Henry Bessemer, who released it after the mid- 19th century in England. It is no longer used today.

In the Bessemer air is blown through the molten blast furnace and very high-carbon cast iron. Of carbon and other elements to burn carbon monoxide, carbon dioxide and other oxides, wherein the temperature of the melt rises beyond the melting temperature of the pig iron of 1,150 ° C at least to that of steel, which can be up to 1,536 ° C. If the carbon content in the iron has decreased below a certain value, steel is formed from the pig iron. When the composition of the desired corresponds to one of ordinary skill in the flame color at the outlet of the Bessemer converter.

The Bessemer converter is a so-called bottom-blowing converter. Thus, the Bessemer method works, the pig iron must be phosphorus and sulfur. Pig iron without this property has been processed in the Thomas pear to steel.

Description of the Bessemer converter

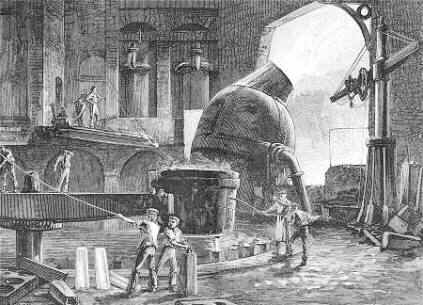

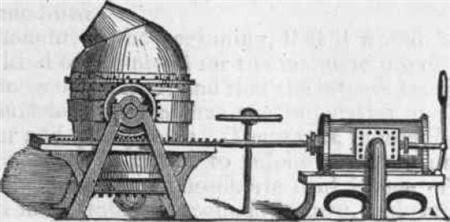

In the Bessemer process to use an oven with movable bulb (converter, retort ). This Bessemer neck with A B consists of sheet iron and is lined with refractory bricks. These bricks are made and baked for the acid process of quartzite, mudstone and small amounts of refractory clay. For the basic process is prepared stones of baked and ground dolomite with dehydrated tar, by the mass of exposing a strong pressure in hydraulic presses. Sometimes the stones are stamped in iron molds and then annealed.

The bottom piece C is either riveted firmly to the main body A, or can be taken away to be rammed full of refractory material in which you let conical openings for receiving seven clay molds, each of which again 7-13 cylindrical channels (nozzle ) of has 9-12 mm diameter for wind supply. K by means of a hydraulic piston is pressed under the base of the bulb of the running rollers to the wind box D. The bulb is suspended in pins a and b, which rest on a rack e. The blower air flows out of the wind pipe tube F through the tube c in a space between the pins a and the rest on the stand E sleeve d and goes through the pipe e in the associated by a bracket f windbox D from which the wind the nozzle enters the bulb.

The regulation of the wind is done by an operator by means of a valve at the wind conduit or wind access regulates the tilt of the apparatus of itself by means of an eccentric ring on the pin A, the stresses during rotation of a lever arm and lower and thus also on the tube opening F in G befindliches, held down by a weight valve. A movement of the bulb takes place g engages by means of a rocker gear H, in which a motion of the piston of a hydraulic press rack.

For large bulbs you used for this operation also steam power, with small winches. Smaller bulbs hold up to 1000, more up to 8,000 kg; such, for example, of 5,000-6,000 kg content has in the middle part 1.5-2 m in diameter and 0.8-1 m height.

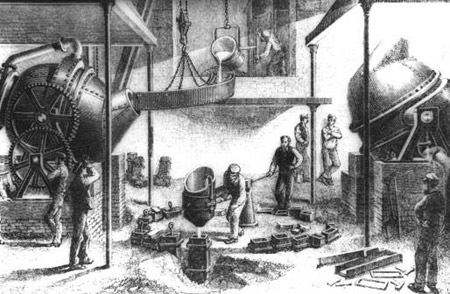

The Bessemer Process

It lets the pig iron flow directly from a blast furnace or a cupola in a channel through the neck of the bulb A 'and then flips it on while automatic Starting the wind. The neck B ' of the bulb A' is then a ' related screen K' with the Esse L.

After completion of decarburization is allowed in a cupola or reverberatory furnace M fused in mirror iron enter through the neck or is red-hot ferro-manganese or silicon iron on, the bulb is directed again to blows if necessary, another 2-3 seconds and then leaves, shut off the Wind 5 - 10 minutes to stand still so absorbed, bubble -generating fonts, allow gases to vent.

Then the bulb A is tilted and its contents emptied into the ladle N, at the end of the balanciers O of a hydraulic piston P is located, which can be raised and lowered. Q is a counter weight at the other end of the balanciers that is moved depending on the content of the ladle N. To fill the standing in a semicircle around the crane iron forms a plug h pulled from an opening in the bottom of the pan and this out by moving the balanciers in a semicircle on the forms by the workers through a coupling gear at i the gear k in the gear l can intervene.

The tilting the ladle N to ensure their cleaning is done by means of the rod m by rotation at n '; o wall plate to protect the crank disks i and n ' rotating worker; pp ' bearing for the pressing cylinder of the hydraulic machine, which is used for movement of the rocker.

Other methods of production of steel

The Bessemer converter is no longer used today. The process was optimized in the 19th century by the Thomas process and later replaced by the inflating converter in the LD method. There are also other methods for steel production: in electric arc furnaces and open-hearth furnaces.

.jpg/250px-Bessemer_Converter_(PSF).jpg)