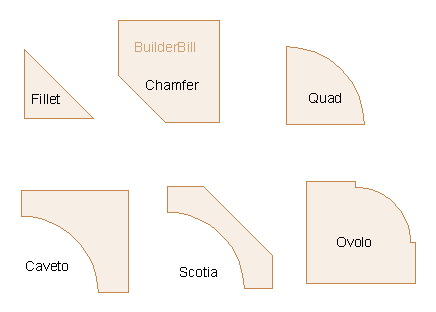

Chamfer

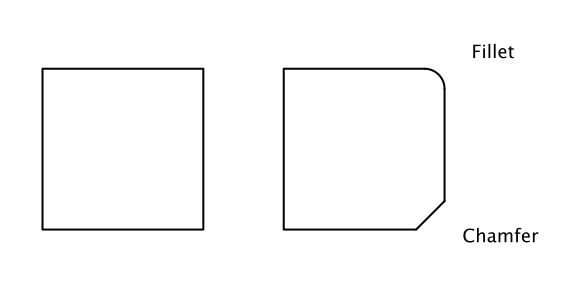

The bevel is a slanted surface, which is generated at a workpiece edge.

Production

At rotationally symmetric workpieces, such as Tubes and waves, the production is done by turning; for other workpieces by milling or planing. Further holes and internal thread are formed by use of sinkers in the drilling or turning. Chamfering be the sharp edges on workpieces, such as boards for wall and ceiling paneling, broken by a so-called chamfer, so beveled along the edge. Depending on the material knife, plane or grinding tools are suitable for chamfering. In concrete parts chamfers are manufactured in the casting process by inserting triangle strips in the formwork.

Shaping

In general, the chamfer on workpieces at an angle of 45 ° to the plane. Wherein bores or internal threads and an angle of 60 ° being common. Chamfers are generally consistent shapes in a continuous workpiece edge. If only portions of an edge to be processed is called a remote chamfer.

Use

Chamfers are often attached to components for removing burrs, reducing the risk of injury and the simplification of the further assembly.

In preparation of welds plates are chamfered at the joints often. As well as holes, to facilitate threading. For plaster or planed or you cut the edges at the joints from, so they can be easily smoothed.

Furthermore, the chamfers are attached to parts, into which a second component has to be introduced. The chamfer serves as an insertion.

An alternative edge treatment is rounding.