Computer-aided quality assurance

Computer -aided quality assurance (CAQ ) stands for computer aided quality assurance and is an element of quality management. CAQ systems analyze (process data analysis, PDA ) to document and archive quality data relevant to manufacturing processes. CAQ includes computer-based measures for the planning and implementation of quality assurance.

Examples are the investigation of the tires of a ICE for hairline cracks or the automatic verification of integrated circuits and printed circuit boards (see also rigid needle adapter). CAQ usually includes in addition to the data acquisition and digitization, transmission and long-term storage of data.

The analysis, documentation and archiving of quality-relevant data is for companies to minimize risks under the product liability law of very high importance. These data measured, attributive and visual tests from CAQ system are evaluated using statistical methods. The CAQ systems also indicate the process capability of manufacturing processes (see also Statistical Process Control, SPC short ), ie, how stable and how well reproducible production processes. Linking such quality-related data with the complaint handling can lead to a significant cost reduction.

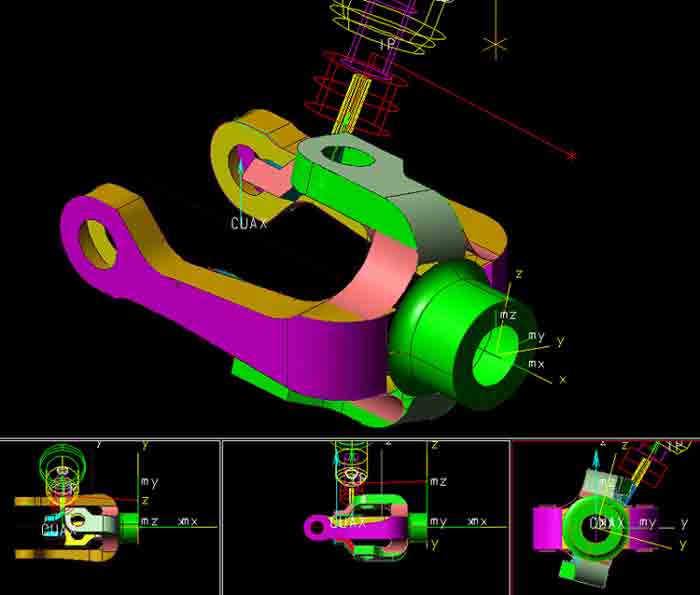

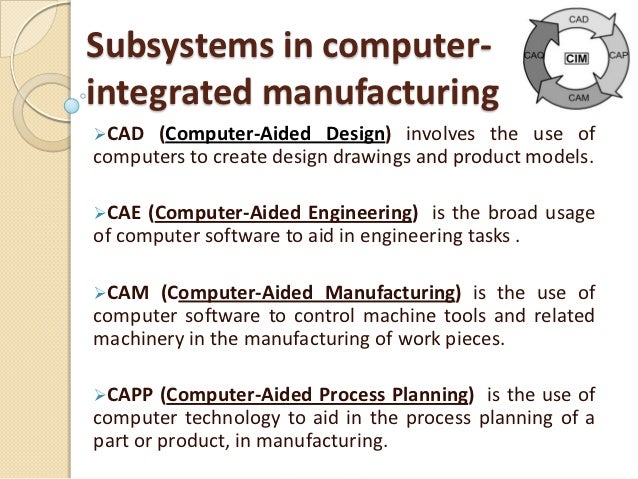

CAQ is part of the computer integrated manufacturing (CIM ) and can be exchanged via the QDX between companies.

Disciplines of CAQ include:

- Incoming inspection and supplier evaluation (including regulated in ISO / TS 16949 ) (WE respect engl. IGI)

- Production Preparatory Examination (machine capability study (MFU ), Measurement System Analysis (MSA ) )

- Production Inspection ( often in the form of statistical process control )

- Outgoing Goods Inspection (WAP, English OGI )

- Audit Office ( Planning and performing audits, and tracking the defects found )

- Effect analysis ( FMEA)

- Document management ( traceability of document changes ) ( DMS)

- Action management ( traceability of measures implementing )

- Complaint Management ( Traceable processing of complaints based on the so-called 8D process; see 8D report )

- Gauge (proof of test equipment capability, calibration and use history )

- First article inspection (detection of potential ability to produce the required quality )

- Quality Planning ( APQP)

- Computer Integrated Manufacturing