Free machining steel

A cutting steel is a steel, which is for the machining processes turning and drilling ( continuous cut) optimized for automated machine tools. By alloying with phosphorus or sulfur is brittle inclusions, where it may break the chips form.

- By alloying with lead arise finely distributed heterogeneous lead inclusions in steel, where it may break the chips. Cutting steels for very high cutting speeds are alloyed with lead. Since toxic lead fumes evolved during alloying from the melt, a special equipment of the steel plant for extraction and separation of the vapors must be used. Therefore bleilegierte cutting steels are no longer produced in large quantities.

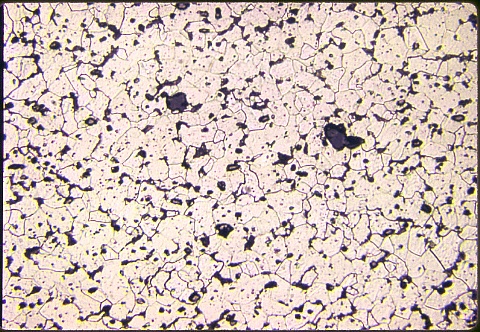

- By alloying with sulfur (0.08 % -0.4 % ) and manganese (0.7% -1.7 %), similar properties can be set as the lead alloy. Through the addition of sulfur arise soft, linearly pronounced manganese sulfide inclusions in steel that break the chips.

Cutting steels are mainly used in series production on lathes and machining centers combined.

The main cutting steels are listed in DIN 1651 / EN 10087 and EN 10277-3.

Some of the best known representatives of the free machining steel are listed in the table.

Chemical analysis / determination of the alloying constituents of the free-cutting steel is usually done with a spark emission spectrometer.