Lumber#Dimensional lumber

Lumber is a wood product that is made by sawing of logs parallel to the stem axis. It can be sharp or have rough edges.

The freshly cut wood ( as a standardized product in accordance with DIN 68252 terms for lumber, shape and dimensions) has initially no building approval for use as a timber (as lumber ) for supporting or bracing purposes. It must first be on a wood moisture content of max. 20 % dried and then sorted according to the provisions laid down in DIN 4074 criteria after load. Some of these sort criteria such as the location and size of branches, the nature, location and depth of cracks, and the slope of grain ( wood fibers should be as parallel as possible to the longitudinal axis of the timber cross -section). Only wood that meets the grading criteria may be used for load-bearing purposes in the construction or bracing.

- 3.1 Germany (and partly Austria )

- 3.2 North America (USA and Canada)

Formats

Depending on the use of the products, different standards with different Maßdefinitionen underlying:

Slice

Depending on how the round wood split ( cut at the sawmill or fogged up) in the processing of logs, designate one different cross-sections. The following applies:

- Is split into the more parts of the stem cross-section, the less twist the woods and the less they pull (because lower cutouts build lower internal stresses)

- Is split into the less parts, more powerful in terms of thrust / train / bending or breaking the wood (because the original fiber structure of the tree is preserved).

Which is the higher quality, depends on the use. For this reason, but good strong timber is sought after as can be gained only from this strongly -sized timber high sorting class.

Delinquent, fully edged and geschwartet

- Full -edged called lumber, clean cut edges has

- Delinquent or tree- edged called timber, which still shows parts of the curve, it is called the forest edge or forest edge

- Geschwartet called the trunk, after an outside rounding was removed on a portion of the circumference, the section is called the rind, it's pretty worthless

In addition, a distinction is still full - edged sap at Heartwood - here the edge is also free from the inferior, outer sapwood.

Types of cuts

- Full wood: the full cross-section used, fully edged or tree -edged, also sap - All wood is approximately square to the cross section of the largest capacity ( 1: √ 2 ≈ 1:1.4 ) and is mainly common for bars or strong timber - weak whole wood called einstielig

- Half Wood: core-separated into two parts - for beams, joists and other timber, common format between 5:7 to 5:10 (1:2 ), formerly popular in carpentry because it represents the best compromise between stability, peace and Price, today replaceable ( glulam )

- Cross wooden or quarter Wood: Quartering - cross wood is called only when the lumber thus produced a cross-sectional area of more than 32 cm ² (that is stronger than a wooden slat ) - Standard in carpentry, minimum requirement for carpenters goods

- Frame: at least 6 piece core-separated from a round timber generated, likewise more than bar

The first three types of cuts we group together as a dressing wooden when it comes to carpentry, finer subdivisions than sawn timber.

In addition, there (and in particular gave ) are still numerous other types of cuts:

- Board cut / hallway interface or gate section: Disassembly of the tribe in a number of boards or planks, either gated directly, and then lined individually, which gives the higher yield, or the tree geschwartet both sides, and then disassembled, the now common, faster way

- Heart hallway section: Here is a hallway directly from the core, or two boards is cut to the core, which deliver a first-class wood for the bottom belt ( strip flooring ) because they have standing annual rings; the rest of the tree is gated

Norms and Standards

Germany (and partly Austria )

- DIN 4074-1 ( 2003-06 ) classification of wood after load - Part 1: Coniferous sawn timber.

- DIN 4074-5 ( 2003-06 ) classification of wood after load - Part 5: hardwood lumber. is also binding as ÖNORM DIN 4074 -x for Austria

- DIN 68252-1 terms for lumber, shape and dimensions.

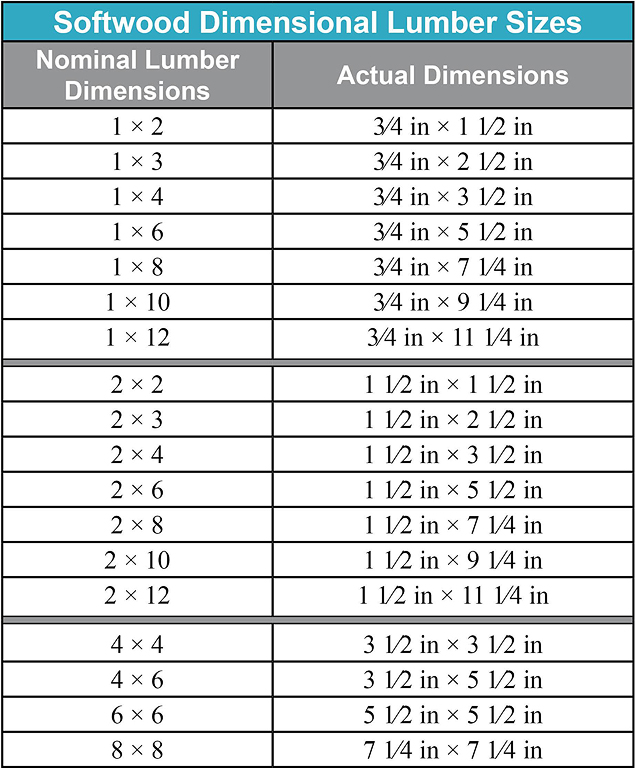

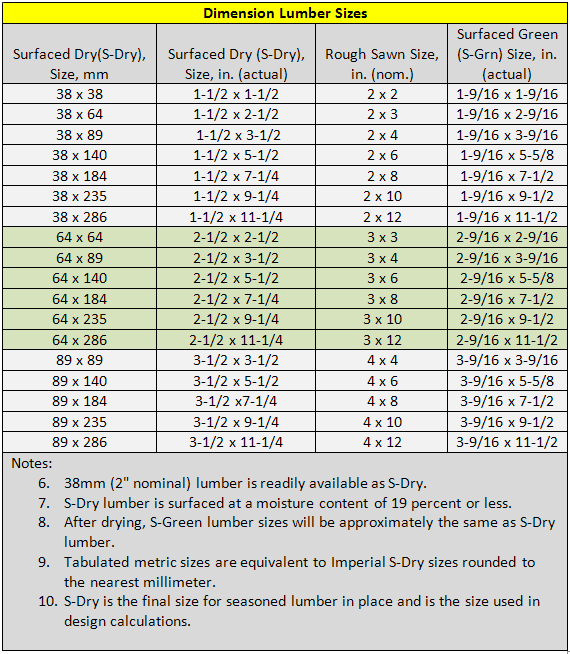

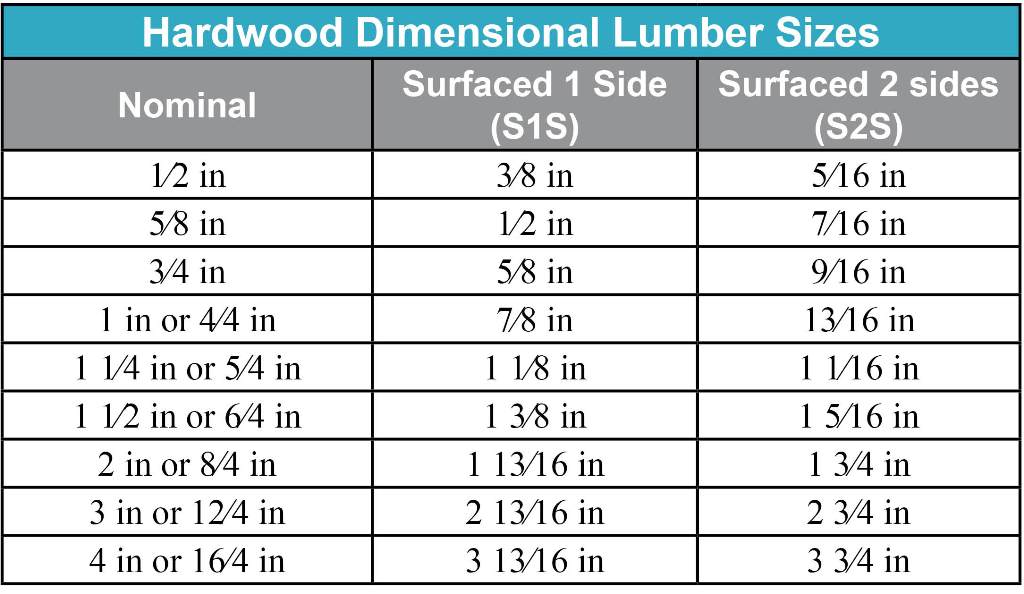

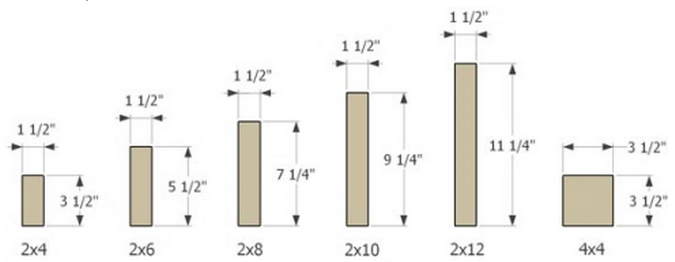

North America (USA and Canada)

- American Softwood Lumber Standard PS -20

- NHLA Rules for the Measurement and Inspection of Hardwoods and Cypress

Economic Importance

More than half of the defeated Germany in forest timber moves in the sawmill industry. The most important sectors for the use of lumber are the construction and furniture industry. The main sales markets for the use of wood products in the construction industry ( Building Construction ) represent the segments building ( wooden building), modernization ( construction work on existing buildings ) and the interior area (floors ) dar. from the timber are mainly wooden houses, roofing, windows and doors and floors ( planks, parquet or laminate ) were prepared. 2003, the consumption was of sawn timber in building construction at about 13 million cubic meters.