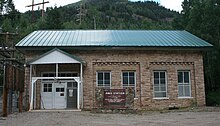

Ames Hydroelectric Generating Plant

F2

The hydropower plant Ames (English: Ames Hydroelectric Generating Plant ) is a hydroelectric power station at Ophir in San Miguel County in the state of Colorado in the United States. It is the oldest commercially -used water power plant that produced alternating current to power machinery and is listed on the List of IEEE Milestones in the development of electrical engineering.

- 2.1 1891-1905

- 2.2 From 1905

History

The gold mines in the area from Telluride ( Colorado) were the end of the 19th century, just before the off, because one end of inexpensive steam propulsion was in sight. The forests around the area were almost completely cut down and the wood has been used either for the mine roof or as fuel for the boilers of steam engines. Other fuels such as coal could be poorly fed because no powerful railroad resulted in the Gebirsgegend over 2600 meter high. LL Nunn, one of the east coast of immigrant entrepreneurs and major shareholder in the Gold King Mine, was looking for a way out of the situation. Looking for a new source of energy, hydropower came into question, but the energy from the appropriate location of a power plant over a several -kilometer route to the mine in Telluride had to be transferred. The then-known techniques for the transmission of energy over long distances were the DC line, cable transmissions or air lines as they were for example used in Paris for driving machines. These techniques were not suitable for all the intended application due to the high Übertragunsverluste.

Nunn learned of his brother, who lived on the east coast of the United States, the new AC technology. The brothers asked Nunn to it George Westinghouse Westinghouse Electric to provide the technology and the equipment for the power plant. Westinghouse agreed because it saw an opportunity, the current war to decide for themselves.

In the summer of 1890, the generator for the power plant and the engine for the mine was delivered. The plant could go into operation in 1891 in the following summer, so the electricity company, founded by the brothers Nunn under the name Telluride Power Company for the first time able to sell their electricity to the Gold King Mine.

The success of the plant decided the current war for the AC and paved the way to the implementation of the first large-scale power plant in AC technology: Located in Niagara Falls, Edward Dean Adams Power Plant took in 1895 to run on, with advice backer in building one of the Nunn brothers.

The power plant was completed in 1892, with further groups of machines, so that other mines could be supplied with electricity. In 1896, the system to the developed by Nikola Tesla 60 Hz system was rebuilt, in 1906 the current machine group has been incorporated. 1911 operated the Telluride Power Company already eight power plants and had a transmission network of 1,000 km in length. The Ames Hydroelectric Generating Plant went through several changes of ownership and part since 1999 Xcel Energy.

Importance in the history of the electric power supply

The power plant Ames is the oldest hydropower plant, which produces alternating current for industrial purposes, ie for driving machines. Although it had a transmission over a longer distance, but used initially no transformers, because the energy was used to power machinery, great performance.

The first AC power supply with different voltage levels was already five years earlier put into operation in the United States. It was located in the resort of Great Barrington in Massachusetts and went on 20 March 1886 in operation. The generator was driven by a steam engine.

The power plant Thornberg when put into production in May 1886 is considered the world's first hydroelectric power plant with feeding into an AC distribution system, which had two different voltage levels.

Technology

1891-1905

The machine set from 1891 consisted of Pelton turbine with its 1.8 meter diameter, via a belt drive with a separately excited AC generator ( salient ) was associated with an output of 100 hp. The water was removed from the accumulated with a dam made of wood and stones Trout Lake and fed via a channel to a timber tank. From there it passed through a single pressure piping to the engine house, which was initially only a wood shed. The single-phase generated had a frequency of 133 Hz and a voltage of 3000 V. He was passed over a 4.2 km long overhead line to the Gold King Mine, where the electricity to power a motor that Identical to the generator in the power plant was. The line consisted of two wires with 5.8 mm diameter, which were performed on wooden telegraph poles. The cost of the wires amounted to only $ 700, which represented only about 1 % of the cost of a direct-current transmission. The plant used no transformers.

Already in 1892 the plant was expanded with a 600 -horsepower generator that powered a 600 - hp engine in the Bear Creek Mine at a distance of 16 km. Later in the year came another 50 hp and a 75 hp engine in the Savage Basin mines to which were 22.5 km away. In 1895 a 100 -horsepower engine was operated in the Pandora Mine also 22.5 km away.

1869, the plant was converted to the developed by Nikola Tesla two-phase alternating current with a frequency of 60 Hz.

Generator from 1891

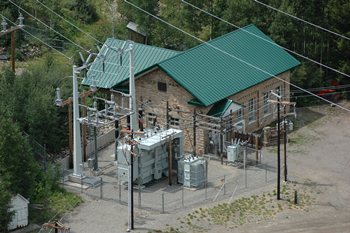

From 1905

In 1905 the plant was adapted to the ever growing demand for electric power. It today's machines set was installed. In order to increase production in the winter months an additional dam was created above the Trout Lake and Lake Hope dammed. The lake has a capacity of 2.8 million cubic meters and an area of 18 hectares. Its water is supplied to the Trout Lake from late autumn through an underground tunnel. In addition, the Howard 's Fork was dammed with a dam. The water from this dam gets its own pressure line to the engine house, where it is processed by a separate Pelton wheel, which sits on the same shaft as the Pelton wheel, the processed water from Trout Lake.

In 1909, the dam of Trout Lakes failed after a flood, so he had to be replaced by an earth dam and it was also increased. The lake has a capacity of 3.9 million m³ of which only 3.1 million cubic meters can actually be used. The surface is 56 hectares, the water level is at 2960 meters above sea level.

In the 1950s, the old wooden structure of overflow were replaced by steel structures.

In the 1980s, the plant was converted to fully automatic operation and extended monitoring of the reservoir. 1997, the transmission line voltage of 69 kV was raised to 115 kV.