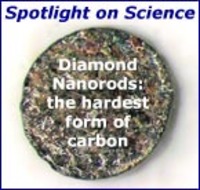

Aggregated diamond nanorod

Aggregated diamond nanorods ( aggregated diamond nanorods, ADNR ) are a particularly dense form of carbon. ADNR carves samples of natural diamond, which means that it is harder and could allow low-wear tools.

Aggregated diamond nanorods are one of the hardest materials known with a static compression modulus K of up to 491 GPa (about 11 % more than diamond with 442 GPa). Its absorption coefficient for X-rays is 0.2 to 0.4 % higher than that of usual diamonds. The reason for this lies in the reduced bond distance of C atoms in the outer layers of the ADNRs.

The preparation of samples was performed in Bayreuth on Bavarian Geoinstitut in high-pressure compression at pressures of 24 GPa. The starting material are C60 fullerenes. Meanwhile, the production of larger quantities succeeded. Typical ADNRs have a diameter of 5 to 20 nm and a length greater than 1 microns.

The material is resistant to the transformation of the diamond structure in a graphite-like structure ( graphitization ) as a natural diamond. From this and from the greater hardness result also potential future fields of application of this material in the field of cutting tools and polishing and abrasive.

The process for preparing the ADNR was published by Natalia Dubrovinskaia, Leonid Dubrovinsky and Falko Long Horst by Bavarian Geoinstitut (BGI ), University of Bayreuth, together with researchers at the ESRF in Grenoble and the University of Applied Sciences Wildau in August 2005 in Applied Physics Letters. The former researchers have investigated the synthesis and method of use account for the production of aggregated diamond nanorods as a German patent.