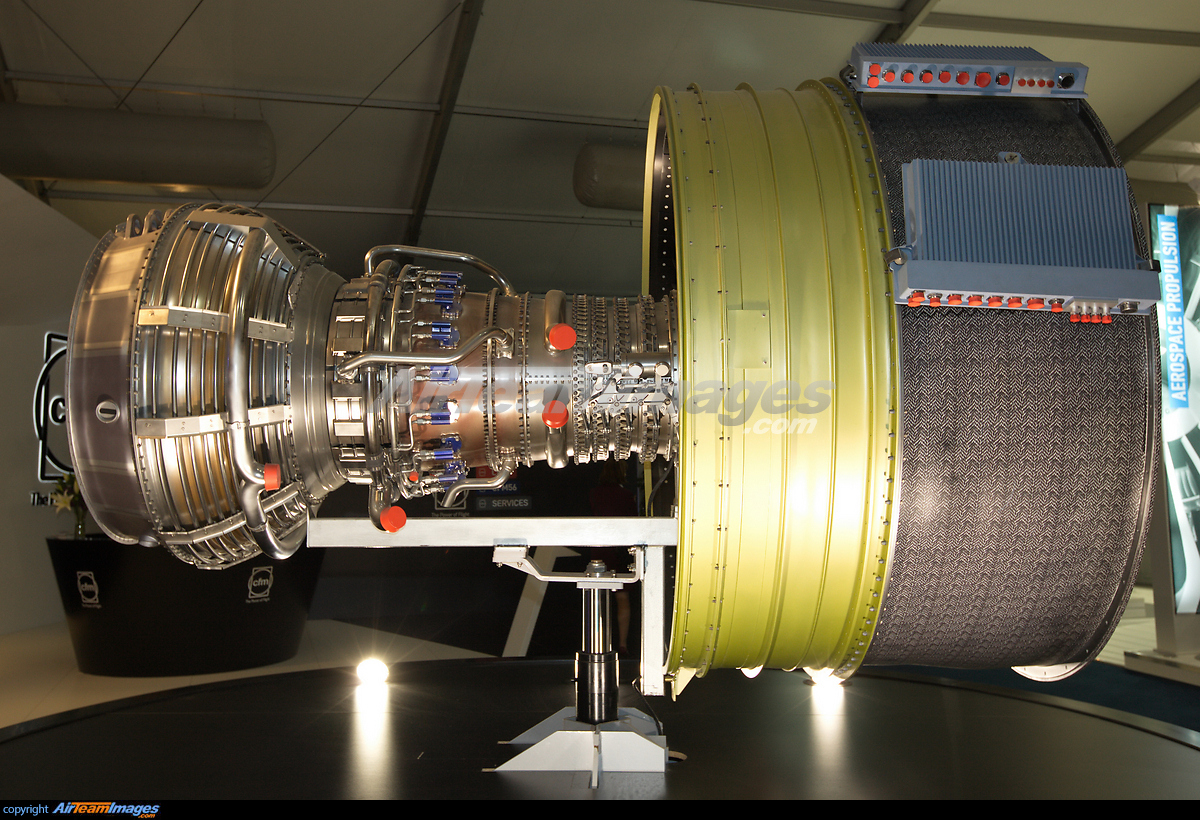

CFM International LEAP

The CFM International LEAP (originally LEAP -X ) is a turbofan aircraft engine manufacturer CFM International, a joint venture of General Electric ( USA) and Snecma (France). GE builds the high-pressure part of the engine, Snecma the low-pressure part. Leap means " jump" or "sentence" and according to the manufacturer also an acronym for Leading Edge Aviation Propulsion, Eng. for " technology- leading aerospace propulsion ".

Development and use

2005 CFM began with a development of the successful CFM56 engine series under the name LEAP56. In 2008 it was decided for the redevelopment of the LEAP -X using the LEAP56 technology. 2012 underlined the manufacturer to the suffix "- X" from the model name. The testing of the LEAP total engine began in September 2013.

From 2016, the LEAP in the Airbus A320neo and Comac C919 of China is to be used. Approval and first flight of the C919 are scheduled for the end of 2014; the A320 approval will follow in 2015. The engine is in direct competition with the geared turbofan engine Pratt & Whitney PW1000G, which is also offered for the A320neo.

Boeing plans to equip the next generation in 2017 their 737 ( the 737 MAX model ) exclusively with LEAP engines after the CFM56 was already the only drive of the 737NG. Because of the much lower landing gear Boeing has to make do with a smaller fan of the new engine as Airbus.

Until November 2011 CFM recorded in 1192 orders for the LEAP -1A, 1876 for the LEAP -1B and 760 for the LEAP - 1C.

Technology

The LEAP is like the CFM56 and the PW1000G a two-shaft engine and belongs to a new generation of engines with high bypass ratio. For the first LEAP models have a 193 cm big fan was originally planned with a bypass ratio of around 10:1, but CFM increased this data at the request of Airbus, " last minute " to 198 cm, and 11:1 to as the A320neo the PW1000G to achieve fuel savings of 15 percent. The fan has 18 blades - only half as many as the CFM56 - which are manufactured with a new process from a lightweight carbon-fiber composite material and are reinforced to the front edges with titanium plates. First ceramic fiber composites can be used for the turbine blades.

As " Ecore " Marked engine core has a ten -stage high- pressure compressor, is driven by a two-stage high pressure turbine. The low-pressure section consists of a three -stage compressor and a seven-point ( Leap -1A and -1C ) or five- ( Leap -1B ) turbine. An adopted and further developed by the General Electric GEnx combustion chamber ( " TAPS II" ) is to halve the emissions of nitrogen oxides.

Because of its size, the engine will be heavier than the previous model, despite the lightweight materials.