Change management (engineering)

The change management (including change management and ÄM (german engineering change management ) ) describes the functions and processes that are established within an organization to perform controlled and documented changes to the products of the organization.

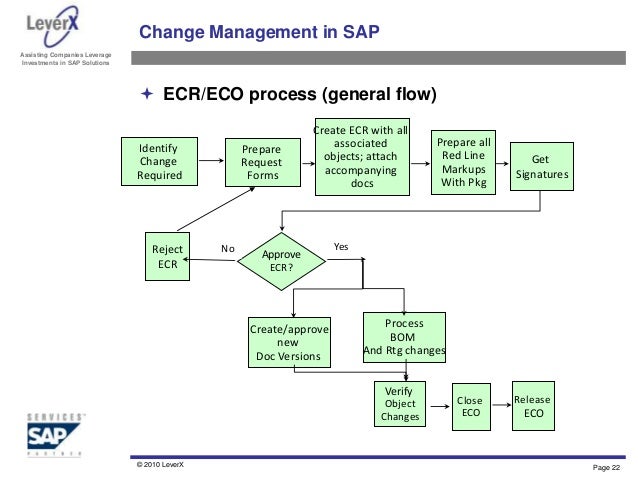

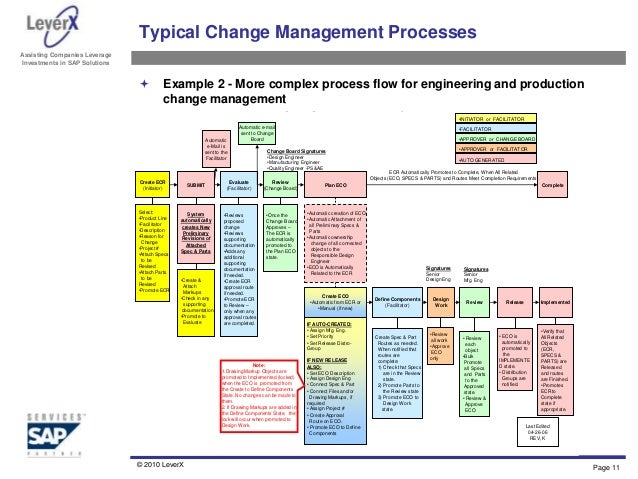

The core element of change management is the change request. After their systematic recording it passes through an approval process. After releasing the change will be implemented through a given target date. The change management can refer to other products of the organization, as well as internal products, especially documentaries. Time plays the change management throughout the product life cycle an important role, that of the invention ( Invention ) to the end of production ( EOP). Particularly critical is the coordinator before the start of production (SOP ), as development times shorten still further, becoming increasingly working in parallel. This coordination is part of the start-up management.

With the well-planned change of organizations, the change management is concerned.

Change management in manufacturing plants

In the development of products usually defined BOM the parts which are included in a final product. With an amendment describes the change is to be carried out on a BOM item and the associated CAD model or the associated parts drawing and what other BOM items are to be taken into account.

The management of changes made in construction projects in a product data management system.

Change management in projects

As part of the project management is understood as change management for the systematic management of changes in the Work Breakdown Structure ( WBS ).

Due to new requirements or suspected error of newly gained knowledge, it may prove necessary to adjust once established plans. Configuration management controls the formal process from application through its approvals to plan adaptation.

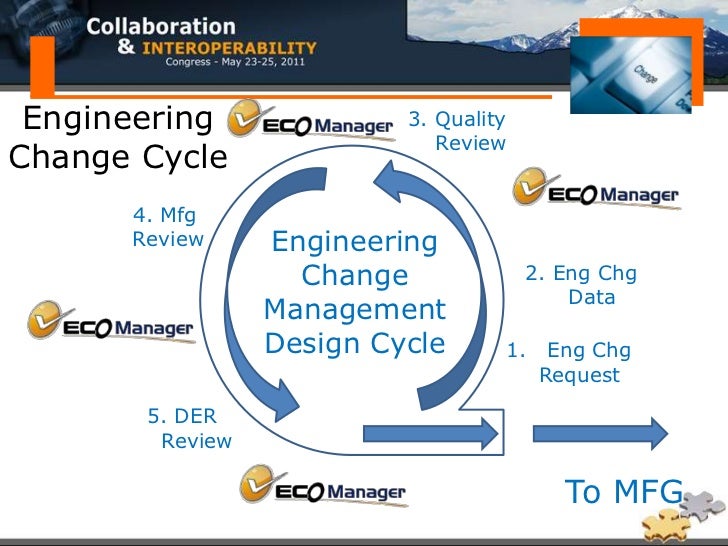

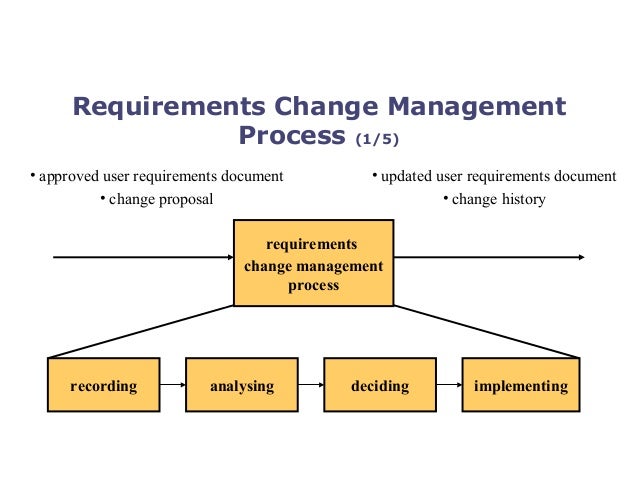

A changing cycle may comprise the following steps:

- Recording of the change request, for example, in the form of an amendment

- Analysis of the Scope of modification ( with the help of respective departments )

- Cost estimate ( material resources, finances, time, etc. )

- Risk assessment

- Decision on the release of the change, contracting, implementation in the departments

- Implementation and documentation of the change

- Qualification and testing of the modified product

- Of its new product

- Possibly transfer into production

- Once the change cycle

Mastery of the change effort

The cost of change management increases with the complexity of the product by the interactions in the system. Interactions occur at interfaces between modules.

The effort in change management can be significantly reduced through strategic modularization with the aim of minimal interfaces between the modules.

Since the modularisation in the design is fixed, there the primary levers are available for expense reduction.

Change management in the automotive industry

Especially in the automotive industry, there are at OEM's sometimes more than 1000 change projects per month, affecting about 7,000 internal and external partners. The solutions range for the technical implementation of a change project of (paper) forms and Excel spreadsheets to specialized IT solutions containing company-specific components.

Often the various solutions are not compatible with each other and have editing breaks between the different partners involved on. Then, data must be entered to change the project several times manually. Through specific different perspectives of an engineer or a businessman also result processing loop for finding solutions, since misunderstandings between the two areas arise. The distribution of relevant information on different management systems ( change management, technical documents, financial calculations) and partners ( OEMs, suppliers) complicates the reconstruction of the decision-making process and makes it impossible.

This can be reduced through harmonization and standardization of the sub-processes of a change project, the processing time between the partners, the process quality and safety can be increased. Thus, the process quality for all partners is transparent. For this purpose, have the VDA (VDA 4965), the ProSTEP iViP eV (PSI 3-2) and the SASIG presents recommendations on how the change management (Engineering Change Management) is to be implemented in various applications.