Chemical bath deposition

The chemical bath deposition ( chemical bath deposition English, CBD, or solution growth) is a coating technique for depositing thin layers. It is based on the controlled deposition of sparingly soluble salts from a solution.

The basis for this deposition technique put Gerhard Brückmann in 1933, when he thin films of lead sulfide (PbS ) established for the first time from a solution of lead acetate, thiourea and sodium hydroxide contained.

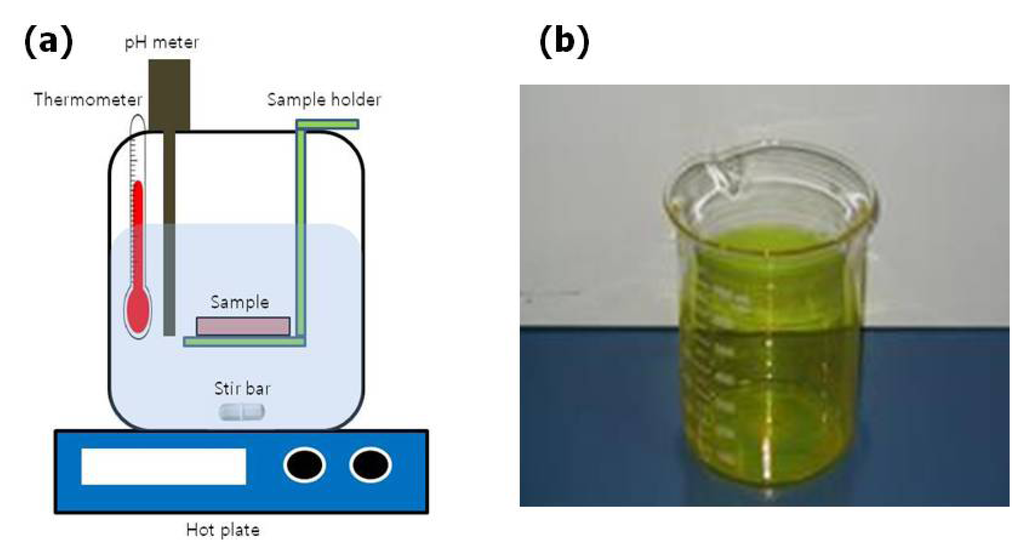

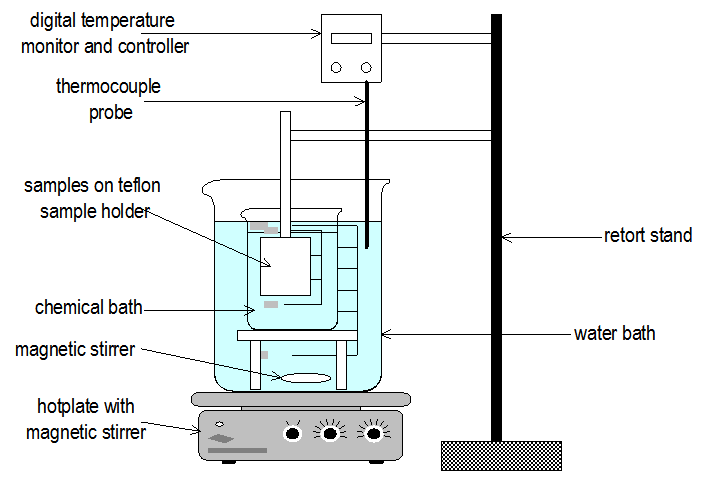

The procedure can be similar to a chemical vapor deposition ( chemical vapor deposition Sheet CVD) are considered, wherein the substrate is not in a gas space, but in a solution. The deposition of thin films is carried out by reaction of the ions or by agglomeration of the colloidal particles. This can be done the solution for example by addition of a complexing agent, and heating. On a laboratory scale this can be, for example, performed as follows. The substrate is in the solution, the one a beaker is immersed and heated by a hot plate at 60 to 80 ° C. For a better mixing of the solution, a magnetic stirrer can be used.

The method is characterized by low cost, since no costly installation is necessary, for example, the necessary with the CVD process vacuum system. Essentially a container for the solution and the substrate is sufficient. In addition, it is considered as a scalable technology, that is, the deposition can be easily transferred from the laboratory scale to large batch or continuous deposition. The disadvantage of this method is that the solution after each deposition is disposed of as waste.

CBD is used inter alia for the separation of chalcogenides, for example, for the preparation of cadmium sulfide layer ( CdS) in thin film solar cells.