Inkle weaving

Weaving band (also ribbon weaving ) is a technique for the manufacture of narrow ribbons, and other fabrics with both ends fixed edges. Textile ribbons are used for technical purposes, as care labels for clothing or labels for branding and as an ornamental for a variety of uses.

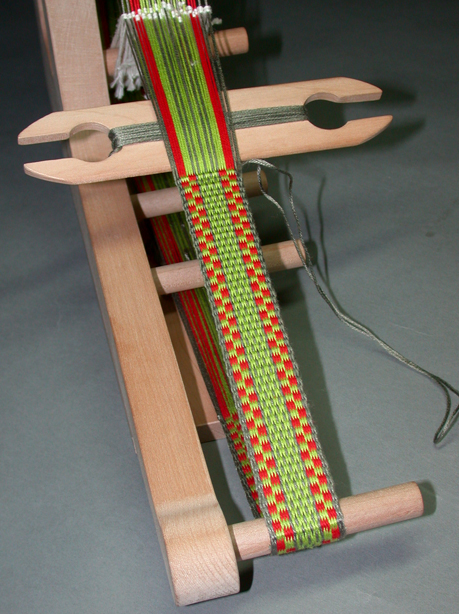

In contrast to the so-called tablet weaving, are also made with the patterned straps, finds the band weaving with the same weaving techniques instead of the other types of flat weaving, ie the tapes are made in plain weave or rib weave with the help of Bandwebstühlen or Bandwebkämmen.

History

Band weaving is an ancient craft. Already the Indo-Europeans have the patterns brought on their walks, which are still woven or are present in museums bands. Around the Baltic Sea, this handicraft has long held.

As industrialization began, ribbon weaver usually presented in homework strips of linen, cotton, silk and other materials on a band active frame or often more popular band chair ago. The house band Weber had a workshop in an attachment called " Shed " their house or in the attic. Its products included inter alia hat, gift and typewriter ribbons. The ribbon weaving was traditionally mainly in the district of Wuppertal Ronsdorf. in Remscheid Lüttringhausen district and the rest of the Bergische Land (where you spoke generally of Ribbon Making ), and located in Saxony and Krefeld.

Even when the Bandwebmühlen revealed the great need for tapes, the home band weaving continued to exist. It was woven on Bandwebkämmen which were richly decorated carved from wood and were often used as a bridal gift. The youngest dated Bandwebkamm dates from the year 1892 ( Jamund ), the youngest band, which is in the museum, dates from 1912 ( Museum of European Cultures, Berlin). Even in 1935, an elderly lady was in the weaving of apron strings photographed ( Jamund ).

Today bands are fabricated on automatically running, weaving machines, on which up to 80 bands can be woven side by side.

Weaving looms

Since about the 1970s, narrow fabrics are predominantly woven on needle looms, only for special purposes, shuttle weaving looms or wide can be used.

Needle looms

Conventional needle looms are designed for different purposes for the production of up to 35 cm wide strips. The machine to be built depending on the width of the woven tape 2 to about 14 Webbahnen. The warp threads are supplied from either the warp beam or from the creel geschärten each Webbahnen. The weft insertion is from one side of the shed with the help of a guide needle and with a speed up to 1500 rounds / min. Knitting needles on both sides of the woven cloth form loops that connect them with each other or with an additional weft and thus solidify the tissue edges. The result is a "real", so do not cut selvedge.

The machine can be fitted with a jacquard mechanism for complex samples containing up to several tens of colors or bands of varying width with two web systems in succession.

Special machines are used for manufacturing elastic tapes, safety belts, of curtain tape, fabric tape, and others.

Schützenbandwebmaschinen

This type of machine allows the efficient production of very dense fabrics or for hoses with tubular branches, as they are needed for blood filter or fuel filter. Shuttle looms can present a maximum of 300 rounds / min at a max. Range of 85 mm to work. The edges of flat strips to be solidified in the control with a specific weave ( hollow weave ).

Machines can be equipped with jacquard and with up to 4 Shot systems over the other.

Width looms

Rapier or air jet looms are used for example for the production of labels. This first manufacture a wide fabric web. The finished fabric is then cut to the loom with a mechanical or thermal cutting apparatus into strips of a width of 6 mm.