Pulverized coal-fired boiler

Pulverized coal is a Staubfeuerungsverfahren for generating thermal energy from ground coal. The method is mainly used in large power plants to use. Due to rising energy prices, the method is also used in smaller systems ( firing of water -tube boilers and cement mills, Trockungsöfen ).

Method

The coal is ground in a grinding mill and dried. It is then either stored in an intermediate bunker (indirect heating ) or directly from the mill outlet ( classifier) pneumatically to the pulverized coal burners promoted (direct firing ). In modern large-scale power plants (200 MW -1000 MW ) direct dust firing are the norm today. Indirect firing systems are often found in cement plants or for smaller boilers.

By grinding up the coal, their surface area increases so much that a rapid combustion is ensured in the combustion chamber. Due to the short reaction times with the combustion air, the stored energy content in the furnace is very low in contrast to the grate. The main advantage of pulverized coal is their better efficiency ( high burnout of coal, lower excess air ) and better (faster ) controllability of the firing.

Commodity

The milling and the grain size of the coal particles depend on the coal used. Be mentioned here as the most important representatives:

- Coal ( grinding up in vertical mills with an outlet grain size of 70 microns and an outlet temperature of about 100 ° C)

- Brown coal ( grinding up in beater mills with an outlet grain size of 100 microns to 1000 microns and an outlet temperature of about 250 ° C)

The coal is delivered to the burner in direct combustion systems in a mass ratio of air to coal of about 2 for indirect firing systems this ratio is partly significantly smaller (up to 0.1 ).

The coal is ground in coal mills. Due to the formation of explosive dust explosion protection measures must be adhered to (eg inerting of the mill). The pulverized coal is conveyed pneumatically to the pulverized coal burner. Dosing the pulverized coal burner and the combustion air into the combustion chamber. Starting up of the boiler and the heating of the lining to the ignition temperature of the pulverized coal is effected with a pilot burner that is fired with natural gas or fuel oil.

Burner

There are numerous shapes and designs of the burner air supply (so-called Luftstufungen ) to make combustion possible in pollutants. The most common objective is the reduction of the burner temperature to reduce the formation of nitrogen oxides. A pulverized coal consists of groups of pulverized coal burners ( usually placed in layers on the boiler ). Generally a mill supplies a group of a plurality of burners in a plane. A large boiler can reach a height of over 150 m. The pulverized coal is located in the lower part of the boiler (up to about 40 m) divided into 3-6 levels, which are respectively arranged a few meters above the other.

Heating

The pulverized coal is mainly used in power plants to generate steam. There are several variations that are mainly characterized by the arrangement of the pulverized coal burner:

Most furnaces are dry-bottom furnaces nowadays. This means that the combustion chamber temperature is below the melting point of the slag. Older systems are designed as a slag tap furnace. One of firing more frequently used in the U.S. is the cyclone, which burns the coal in the burner ( cyclone burner ) and also is a melting firing.

Modern pulverized coal furnaces of coal boilers have about 4-10 mills per boiler and 16-40 burner. Such a furnace burns between 100 t and 400 t of coal per hour.

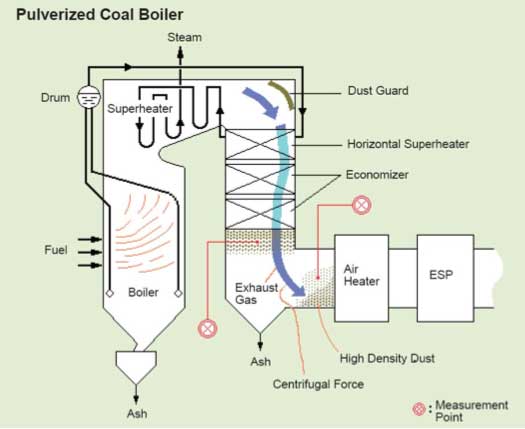

Ash

The obtained in the furnace ash falls either down or is discharged with the flue gas from the steam generator. In the discharge in dry form it is called the dry ash. A special design is the slag tap. Here, the combustion chamber temperature is so high that the ashes can be deducted liquid (as slag). For the deposition of the fly ash from the flue gas in the downstream flue gas cleaning electrostatic precipitators or fabric filters are often used.

History and Use

The pulverized coal was first built in the U.S. in the early 20th century. There are currently built each year over a hundred of these coal large combustion plants, mostly in India and China.

In addition to using stationary driven systems, the pulverized coal was also used in steam locomotives. Here it has not been successful because of the burner output constantly changing. Since a steam engine the firing must be regulated continuously and the Kohlestaubfeuerung einspeichert no energy, never optimal combustion performance can be achieved.

The German cargo ship Nicea in 1934 was converted to coal dust. However, the technique could also not enforce, especially since the steam drive was replaced in the shipping industry in the aftermath of marine diesel.

Efficiency and use

With the strong increase in energy prices of oil and gas, the dust firing has also established itself in smaller and medium-sized combustion plants. In addition to municipal and industrial heating and power plants lignite dust ( UCS) used mainly in the production of asphalt, cement and lime industry. These distributed systems usually have no own lignite treatment, but store the finished brown coal dust explosion protected silos. The delivery of fuel from the operation of the coal upgrading the consumer is made by silo trucks or railroad cars. These furnaces have capacities of about 5 to 15 MW and can replace traditional energy sources in certain areas of the industry.

Developments

Braunkohlenstaubfeuerungen (UCS - firing ) in combination with industrial boiler systems are being tested in pilot projects in Europe, including in low-CO2 - free or even execution. Located adjacent to the Schwarze Pumpe power station in Lower Lusatia, a fired with brown coal dust 30 MW steam boiler in operation, the pure oxygen is supplied for combustion. When exhaust gas is obtained by the condensation of water vapor almost pure CO2 condensed ( liquefied) is. This then allows the dumping of the waste gases from underground.